We have rich experience in the design and production of prototypes, we can provide you with very high-precision prototypes with fast delivery at a low price.

With a range of technologies at our disposal, we can produce any type of prototype needed.

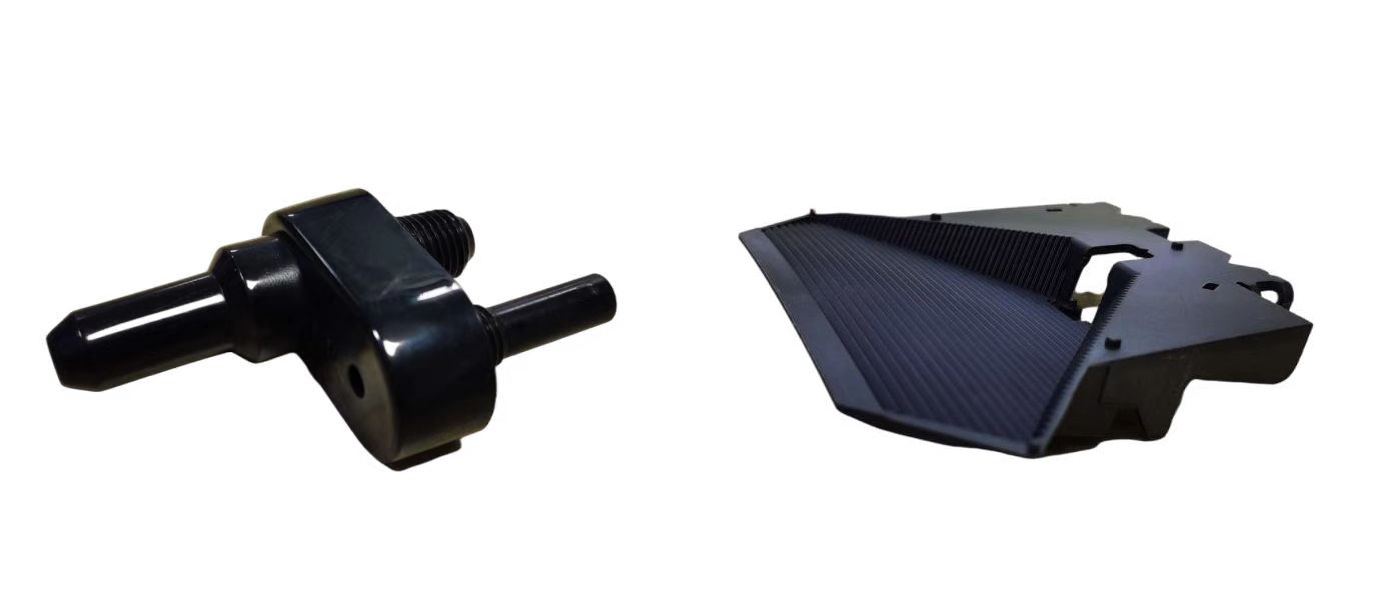

CNC machined prototypes are available in a huge range of plastics, metals, and modeling boards. Many customers turn to CNC machined prototypes to have their prototypes produced out of real material rather than a simulant. We can help you decide whether a CNC-machined prototype is right for your project.

*CNC Machining Highlights

• Machine a wide variety of plastic and metal material options

• Typical accuracy is +/- 0.08MM

• Ability to hold tight tolerances

SLA & SLS prototypes are ideal for rapid, one-off prototypes. SLA prototyping is a process whereby a laser transforms a liquid photopolymer into a solid plastic prototype, layer by layer. SLS prototyping is a similar manufacturing process to SLA, but SLS uses a much higher-powered laser to bond plastic powder together to form a 3D prototype. We have solid experience in producing accurate SLA & SLS rapid prototypes.

3) Polyurethane vacuum casting

Polyurethane vacuum casting allows for an extended prototyping service through a multi-step process. It involves first making a prototype via SLA and SLS, then creating a silicone mold around the prototype to easily manufacture multiple identical polyurethane prototypes.

We also make master patterns for vacuum casting by CNC machining, This process is often preferable if the master pattern is bulky or thick. CNC machining is also the chosen process if the vacuum castings must have an excellent gloss finish or are to be clear. For these castings, We will CNC the master pattern out of PMMA and hand-polish to achieve the gloss.

4) Molded prototypes

Focusing on manufacturing injection molded prototypes for more than 20 years.