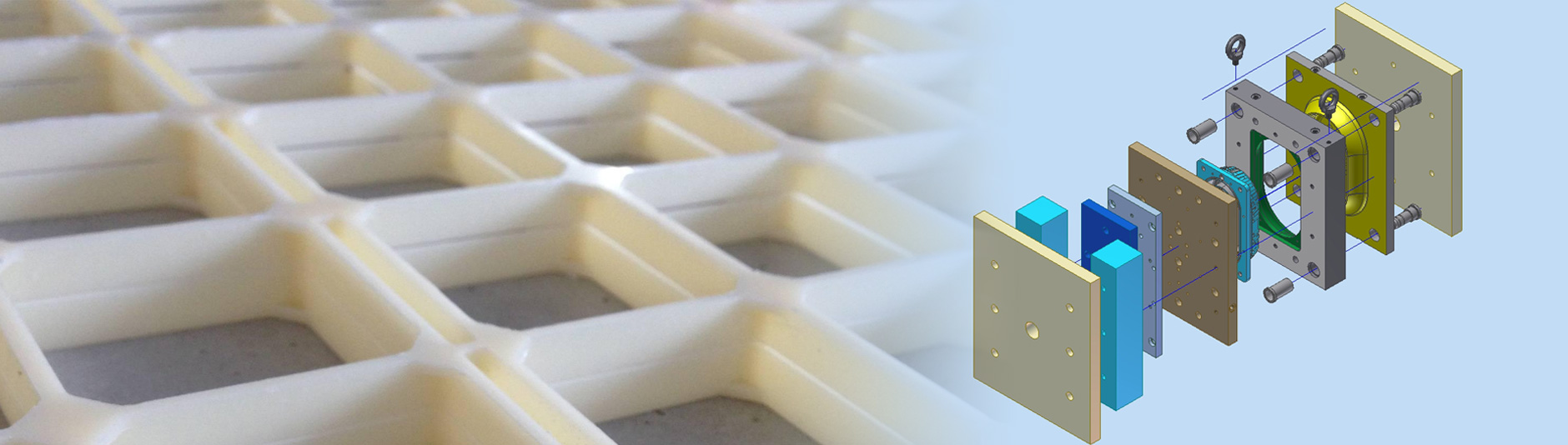

Providing High-precision mock-ups, prototypes, and low-volume production services including small batch injection molding and assembling!

What do we do?

When you want to make a prototype with the same precision as mass production, When you want to make a prototype by which not only you can verify the appearance, the structure, the function, but also you can verify the performance of the materials which to be used in mass production,

Or, When you want to produce a small batch of the new product to launch it to market quickly to see the reaction from the market.

Contact us now, we can just do it for you!

Who we are?

HPDI (Huawei Product Development Industrial Ltd) is a professional manufacturer dedicated to high-precision prototype manufacturing and small batch production.

For More than 10 years, we have provided tens of thousands of prototypes for world-famous manufacturers in the automotive, the communication, the medical, and the aerospace industries.

We are specialists in the manufacturing of all kinds of prototypes and low-volume production service, Besides, We can provide our clients with one-stop service from industrial design,prototyping, prototype injection mold, regular injection mold fabrication, and small batch injection molding all the way to manufacturing products.

Our services are covering with CNC machining, 3D printing, vacuum casting, prototype injection molding, rotational molding, compression molding, Vacuum forming, lost wax casting, metal parts lather cutting, stamping, sheet metal, forging, die casting, small batch injection molding, and low volume production.

Ours Core competencies

-Technology of molded prototypes injection and prototype injection mold fabrication

The accuracy of our Injection molded prototypes is almost the same as mass production, Which can help our customers to shorten the development cycle and reduce the development cost and manufacturing costs.

We have rich experience in Prototype injection molding. And We have the know-how to make the high-precision prototype injection mold within a very short lead-time in a low-cost way, which can help our customers keep their competitive advantage in the market.

We make the prototype injection mold under the same conditions as regular molds, such as using the same steels and use the same plastic materials to inject the prototype, So the accuracy of our molded prototypes is almost the same as the regular injected parts. thus it can help our clients to do the test to check and verify overall performance index and production stability before mass production:

1, Verification of the plastic parts design

2, Verification of the mold design

3, Verification of the resin flowability

4, Verification of the Function and the strength of the plastic parts

5, Verification of the overall performance index of the plastic parts

The advantage of the injection molded prototypes are:

-The Quality level similar to traditional mold

-Plastic materials is the same as the one used in mass production

-Shorten the development cycle

-Save overall development cost

-Get you the new product lauched to the market quickly

Industries

Our Molded prototypes are mainly used for testing and verification or pilot run production of the precision structure parts used in automotive, aerospace, communication, and medical industries.

Automotives, Aerospace, Communications and Medical industries

Some precision interior structural parts needs to work under the strict environmental conditions, and needs to be resistant to high temperature, cold, durability and high strength to ensure good quality and safety, Such as connectors, fasteners, the parts inside engine, gear box and automatic transmission.

It is necessary to verify and test every index of new developed project before mass production. The injection molded prototypes can meet the requirements of such inspection and testing very well.

Besides molded prototypes, We also provide our client with small-batch injection molding services:

-Prototype injection mold fabrication

-Short, medium, and long runs of molded plastic parts

-Small batch injection molding

-Low-volume production

The accuracy of our molded prototypes is almost the same as the regular injected parts. Thus it can help our clients to do the test to check and verify the overall performance index and production stability before mass production.

Our services are covering with CNC machining, 3D printing, vacuum casting, prototype injection molding, rotational molding,compression molding, Vacuum forming, lost wax casting, metal parts lather cutting, stamping, sheet metal, forging, die casting, and so on.